|

|

Build Your Online Product Catalogs?

| Product Name: |

Tug mill for grinding

|

| Supply Ability: |

|

| Related proudcts |

|

| Specifications |

Tug mill for grinding |

| Price Term: |

|

| Port of loading: |

|

| Minimum Order |

|

| Unit Price: |

|

|

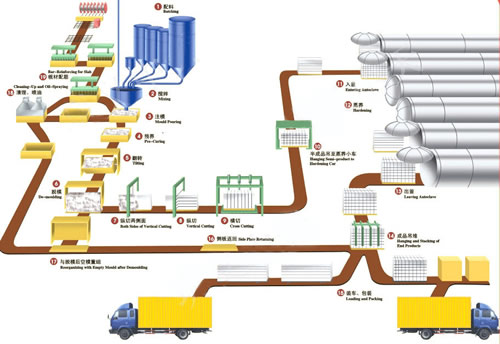

Tug mill for grinding various ores and other materials , are widely used in mineral processing , building materials and chemical industry can be divided into dry and wet grinding methods . According to different ways of discharge can be divided into tabular type and flowing type two. Our customers can design various beneficiation processes , providing tug ball drawings.

Tug mill use and the use of:

Tug Ball is the material after being broken, and then to smash the key equipment. It is widely used in cement, silicate products , new building materials, refractories , chemical fertilizer, black and non-ferrous metals and glass ceramics and other production industries of all kinds of ores and other grind-able materials dry or wet grinding.

Tug mill works:

The ball mill is a horizontal cylinder tugboat rotating device , outer gear, the two positions, lattice energy-saving ball mill. Material from the feed device evenly into the mill first position into the compound empty -axis spiral , the warehouse has ladder liner or corrugated liner, built with different specifications steel ball , rotating cylinder produces centrifugal force to the ball a certain height after the fall, have severe i***ct on the material and abrasive. Material in the first position kibble , after single-co***rtment plate into the second warehouse, the warehouse lined with flat lining , the steel ball, the material to further grinding. Powder through the discharge grate plate to complete the grinding operation.

Tug mill structural features:

I plant the ball in the energy saving ball mill tug update again reduce power the machine consists of feeding part, discharging part, turning part and driving part ( reducer, small transmission gear , motors , electrical control ) and other major components. Hollow shaft with steel , lined with removable, rotary gear hobbing by casting , the body inlaid cylinder liner wear, has good abrasion resistance . The machine running smoothly , reliable work.http://www.yfballmill.com

http://w |

| Company: |

China Top Yufeng Co.,Ltd

|

| Contact: |

Mr. zzdhchris zhou |

| Address: |

Mazhai Industrial Park, Zhengzhou city, Henan, China |

| Postcode: |

45000 |

| Tel: |

8613526817088 |

| Fax: |

037163304116 |

| E-mail: |

|

|

|

|